Processing Materials

CNC machining technology utilizes computer-controlled machines to precisely perform cutting, milling, drilling, grinding, and other operations on metals and other materials. However, different metals have distinct mechanical properties and suitability. Therefore, when choosing materials for machining, it is necessary to consider not only the application requirements of the product and the influence of metal characteristics on cutting but also the material cost, which usually represents a significant portion of the total product cost. Assisting customers in selecting appropriate materials is also a crucial analysis task during the development and design stage.

Metals suitable for machining

The materials we use for CNC milling include aluminum, iron, copper and other metals:

![]() Advantages : Lightweight, high strength, high ductility,

excellent thermal conductivity, easy to machine.

Advantages : Lightweight, high strength, high ductility,

excellent thermal conductivity, easy to machine.

![]() Applicable industries : Aerospace,

marine, automobile, bicycles, electronic products, medical equipment, consumer

goods, etc

Applicable industries : Aerospace,

marine, automobile, bicycles, electronic products, medical equipment, consumer

goods, etc

Aluminum is a commonly used material in CNC machining and is also one of our areas of expertise. It is widely utilized due to its ease of cutting and milling, excellent machinability, and the availability of various alloy types. Aluminum is extensively used in industries that require lightweight and high-strength components. It is considered one of the most cost-effective metals for such applications.

Common aluminum alloys include 7075, 7050, 6082, 6063, 6061, 5754, 5083, 5052, 4140, 4130, 3004, 3003, 1100, and 1060. While they are all aluminum materials, their alloy properties are slightly different. In terms of selection, it is necessary to consider the actual application requirements. Here are some examples :

- 6061 is a high quality aluminum alloy produced through heat treatment and pre-stretching techniques, with magnesium(Mg) and silicon(Si) as the main alloying elements.

- The strength is about 2/3 of 7XXX series aluminum alloy, making it is suitable for products with general strength requirements.

- It has high toughness with good tensile and bending properties, resulting in less deformation after processing.

- Excellent machinability and weldability, making it easy to create different shapes and sizes of parts.

- Good corrosion resistance, suitable for coloring, exhibits excellent oxidation effects, and has good electroplating properties.

- 7075 is a cold-treated forging alloy with zinc as an alloying element.

- It is one of the strongest aluminum alloys and is commonly used in aerospace, automotive and military fields.

- It has lower toughness compared to other aluminum alloys, making it more prone to fracture.

- It has good machinability, but due to its high hardness, high-speed machining and careful attention to the processing temperature are required.

- Its corrosion resistance is ordinary, but it can be enhanced through surface treatment and film formation processes.

In summary, 6061 offers moderate strength and good toughness, 7075 provides extremely high strength and medium toughness, and another commonly used alloy, 6082, has properties between 6061 and 7075. Therefore, selecting the appropriate material depends on the specific application requirements such as strength, ductility, or complexity of the part. These factors need to be considered to ensure optimal performance and usability of the product.

Iron is a metallic element that exists widely in nature. It has excellent mechanical properties and can be used in various industries, including construction, automobiles, machinery, and energy. Pure iron exhibits good magnetic and electrical conductivity and can be alloyed with other elements to modify its properties and create different alloys. In CNC machining, these materials are typically classified into two main types: carbon steel and stainless steel.

Carbon Steel

![]() Advantages : High strength, high hardness, lower cost, suitable for CNC machining.

Advantages : High strength, high hardness, lower cost, suitable for CNC machining.

![]() Applicable industries : Construction, machinery, cutting tools, steel drills, springs, etc.

Applicable industries : Construction, machinery, cutting tools, steel drills, springs, etc.

Carbon steel refers to iron-based materials with a high carbon content. It usually requires tempering treatment to enhance hardness after machining. The higher the carbon content, the greater the hardness, strength and wear resistance of the heat-treated parts will be.

Common material specifications include low carbon steel such as S15C and S20C, medium carbon steel like S45C and S50C, and high carbon steel such as S75C and S70C.

Stainless Steel

![]() Advantages : High strength, corrosion resistance, high temperature resistance, good ductility, beautiful appearance.

Advantages : High strength, corrosion resistance, high temperature resistance, good ductility, beautiful appearance.

![]() Applicable industries : Food, medical, chemical industry, catering, consumer products, etc.

Applicable industries : Food, medical, chemical industry, catering, consumer products, etc.

Also known as “white iron”, stainless steel is a special alloy steel composed of several metals in different proportions. Chromium (Cr), with a proportion greater than 10.5%, is the primary alloying element. It forms a transparent and dense layer of chromium oxide on the steel surface, preventing oxygen from coming into contact with the iron, thereby reducing the likelihood of rusting compared to carbon steel. This is why it is called stainless steel. Other added elements include Ni (resistant to acid and alkali), Mn (reduces processing costs), and Mo (increases hardness, strength, and corrosion resistance), among others.

Different proportions of stainless steel exhibit different properties and have varied uses. Therefore, it is important to understand the characteristics and suitable applications of different grades before selecting a machining material. Here are some examples :

- SUS304 is the most widely used stainless steel. It offers good machinability, high toughness, no hardening phenomenon after heat treatment, and is non-magnetic. It is mainly used in industries that require good corrosion resistance, heat resistance, and high appearance requirements, such as kitchen utensils, furniture, cosmetic containers, and chemical equipment.

- SUS316 is the second most widely used stainless steel with a higher price. Due to the addition of Mo, it exhibits better resistance to chloride corrosion compared to SUS304. It finds applications in the food industry, surgical equipment, marine industry, pharmaceutical or chemical industry that demand higher corrosion resistance.

- SUS303 is an ideal material for producing accessory fasteners because it is easier to cut than SUS304 due to the addition of a small amount of sulfur and phosphorus.

- SUS430 has low carbon content, good formability and resistance to nitric acid corrosion. It finds widespread use in automotive trim and related components, as well as fasteners, tableware, furniture, and washing machine interiors.

Since stainless steel generally has low carbon content and high hardening resistance, CNC machining can be more challenging and requires higher levels of technical expertise and equipment. Attention should also be paid to tool wear, chip handling, parameter setting, and oil selection, among other conditions, during the machining process.

![]() Advantages : Good electrical conductivity, good thermal conductivity, high malleability, high ductility, corrosion resistance.

Advantages : Good electrical conductivity, good thermal conductivity, high malleability, high ductility, corrosion resistance.

![]() Applicable industries : Electronics, electrical appliances, communication devices, construction, manufacturing, etc.

Applicable industries : Electronics, electrical appliances, communication devices, construction, manufacturing, etc.

Copper is a red-colored metal with a softer hardness compared to other metals, but it is still suitable for CNC machining processes such as cutting, milling and drilling. Due to its high electrical and thermal conductivity and ease of welding, copper is commonly used as an engineering material. The purity of pure copper can exceed 99.9%, but in practical applications, it is often mixed with other metals to form various copper alloys. For example, bronze and brass are commonly used in electronic parts.

Brass

![]() Advantages : High machinability, corrosion resistance, aesthetic appearance, high ductility.

Advantages : High machinability, corrosion resistance, aesthetic appearance, high ductility.

![]() Applicable industries : Metal fittings, mechanical parts, pipes, decorations, etc.

Applicable industries : Metal fittings, mechanical parts, pipes, decorations, etc.

Brass is an alloy mainly composed of copper (Cu) and zinc (Zn), typically containing 40% to 50% zinc, showing yellow or golden color and has excellent machinability. Despite slightly higher raw materials costs, it has a relatively high waste recycling rate. Common types like C360 and C260 have a higher zinc content, making them soft and easy to process, resulting in less tool and equipment wear. Brass is a cost-effective category of material.

Moreover, its attractive golden color adds artistic value to its appearance. In addition to industrial applications, brass is commonly used in the production of musical instruments, artworks, bathroom fixtures and other products.

Bronze

![]() Advantages : Wear resistance, corrosion resistance, high-temperature resistance, good casting performance.

Advantages : Wear resistance, corrosion resistance, high-temperature resistance, good casting performance.

![]() Applicable industries : Machinery, ships, electrical appliances, construction, etc.

Applicable industries : Machinery, ships, electrical appliances, construction, etc.

Bronze is composed of copper (Cu) and tin (Sn), usually containing 5% to 30% tin. Although tin metal is slightly white, it easily oxidizes when exposed to the atmosphere, resulting in a green or dark brown appearance. Bronze is one of the earliest known alloys. Due to its higher corrosion resistance and wear resistance, it is often used to make bearings, gears and other components.

![]() Advantages : High strength, low density, lightweight, corrosion resistance, high-temperature resistance, excellent biocompatibility

Advantages : High strength, low density, lightweight, corrosion resistance, high-temperature resistance, excellent biocompatibility

![]() Applicable industries : Aerospace, aviation, medical equipment, military, advanced engineering, etc.

Applicable industries : Aerospace, aviation, medical equipment, military, advanced engineering, etc.

Titanium is a lightweight and high-strength metal. It possesses properties such as high strength, excellent corrosion resistance, thermal conductivity, good biocompatibility, and low density. Despite the high processing difficulty, titanium is still widely used in high-end industries such as aerospace, medical, and defense.

Compared to steel, titanium is stronger, and compared to aluminum, it is less dense. This allows for the manufacture of high-strength, low-density, and lightweight components, thereby improving the performance and fuel efficiency of aircraft. The dense oxide film formed on the surface of titanium provides resistance to acid and alkali substances, protecting the material from corrosion in humid or high-temperature environments and extending the lifespan of components.

It is worth mentioning that titanium materials also have the advantage of high biocompatibility. When in contact with biological tissues, they are less likely to cause adverse reactions or rejection. Titanium is commonly used in the medical and biotechnology fields, including artificial joints, heart stents, dental implants and more.

Utilizing CNC machines to process titanium enables the production of parts with high precision and complex shapes. However, working with titanium requires the use of cutting tools with high hardness and wear resistance. It is also necessary to employ lower cutting speeds and larger feed rates to avoid issues such as thermal deformation of the workpiece and damage to cutting tools.

Alloys are materials formed by combining two or more metals, and they offer superior performance and characteristics, making them a popular choice in CNC machining. Different types of alloys possess unique properties, such as high strength, high temperature resistance, and corrosion resistance, which can be tailored to meet specific application requirements. For example, aluminum alloys are commonly used in the aerospace and automotive industries, nickel alloys are widely used in the energy and petrochemical sectors, and zinc alloys are easily cast and processed, making them suitable for industries like construction and electronics.

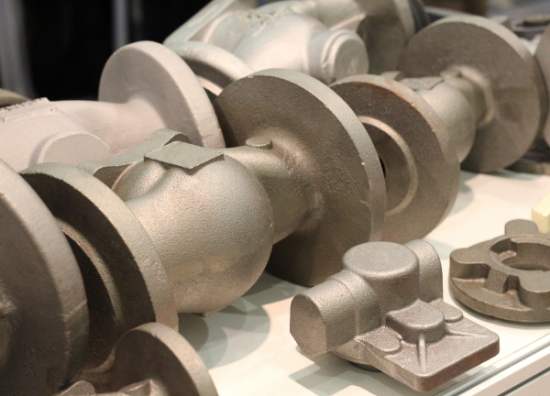

The above are common metal raw materials used in CNC machining. When manufacturing parts for various industries, the initial step typically involves shaping the metal raw materials into the desired form using different metal forming methods. The common ones are forging, casting, and extrusion :

Process : Solid metal → Cutting → Pre-heating → Forging → Stamping → Heat treatment → Polishing → Tumbling → Sandblasting

Forging is a metal shaping process that involves applying pressure to a metal workpiece using forging machinery to acheive the desired shape. It allows the metal to attain specific mechanical properties, shape, and dimensions. Depending on the forging temperature, it can be classified as hot forging (above 800℃), warm forging (300℃~800℃), or cold forging (room temperature). Hot forging is the most commonly used technique in many industries.

During the forging process, the metal undergoes deformation under applied force, which can eliminate defects such as casting porosity that may occur during the metal’s initial production stages. It retains complete metal flow lines, resulting in better mechanical performance compared to castings of the same material. Common materials used for forging include various grades of carbon steel, alloy steel, aluminum, magnesium, copper, and titanium alloys.

- Advantages : Lightweight, high strength, high production efficiency, reduced subsequent processing hours, ability to produce complex-shaped parts.

- Disadvantages : Higher tooling and manufacturing costs.

- Applicable industries : Automotive, motorcycles, bicycles, machinery, etc.

Process : Molten metal → Molding → Solidifying and cooling → Cutting off → Grinding → Blasting → Heat treatment

Casting is a metal forming process where heated molten metal is poured into a mold to obtain the desired shape. It can be categorized into different casting types according to the mold and process used, such as gravity casting, die casting, low pressure casting, sand casting, lost wax casting, vacuum casting, continuous casting, etc.

Gravity Casting

It is usually used for producing large metal components like engine blocks, axles, bridges, etc. Gravity Casting is a molding method where the molten metal, under the influence of gravity, takes the desired shape within the mold. It is a type of permanent mold casting. Generally speaking, the permanent molds used in gravity casting are made of heat-resistant alloy steel, allowing for high reusability, high production efficiency, and excellent dimensional accuracy of the parts.

Due to its high thermal conductivity, large heat capacity, and fast cooling rate, parts produced through gravity casting show good casting structure, surface roughness, strength, and dimensional precision.

- Advantages : Long mold life, high precision, smooth surface, and high strength.

- Disadvantages : Higher mold cost, less suitable for small quantity production.

- Applicable industries : Automotive, motorcycle, machinery, hand tools and other parts.

Die Casting

Die casting is the most commonly used method in permanent mold casting, which uses high pressure to inject molten metal into a mold to achieve the desired shape. The metal is usually non-ferrous metal or alloy, such as aluminum, zinc, magnesium, tin, and copper.This method is often employed for mass-producing thin-walled, complex, and small parts, such as automotive body components, machine parts, household appliances, casing of electronic devices, or various other components.

- Advantages : Suitable for mass production, reusable molds, fast processing speed, precise and consistent dimensions, reduced post-processing time.

- Disadvantages : Higher cost of equipment and molds, not suitable for producing small amount of diverse products.

- Applicable industries : Automotive, machinery, electronics industry.

Lost-wax Casting

Also known as investment casting, it is one of the oldest known metal forming methods. Lost-wax casting has been used in ancient civilizations such as Ancient Egypt and the Spring and Autumn period of China for casting bronze artifacts. It is a process that invests wax pattern with refractory material and a binding agent to shape a disposable ceramic mold, and then molten metal is poured into the mold to make metal castings.

Investment casting offers the advantage of producing highly complex and intricate castings with high surface smoothness. Wall thickness and internal structure can be precisely controlled during the manufacturing process. It is suitable for casting various alloys, including aluminum, magnesium, copper, steel, and different shapes and sizes of parts.

- Advantages : Ability to produce parts with thin-wall, complex shapes, high surface quality, high dimensional precision, and reduce post-casting machining.

- Disadvantages : Non-reusable molds, higher manufacturing costs of molds, labor-intensive.

- Applicable industries : Gears, turbine blades, engine blades, medical equipment.

Process : Solid metal → Cutting → Pre-heating → Extrusion → Straightening → Cutting → Heat Treatment

Extrusion is a hot forming method in which a metal material is continuously passed through a die with a predetermined shape at extremely high pressure and temperature, by heating, plasticizing and screw extruding, and then cooled to form the desired shape. It is typically used to produce long or continuous shape parts such as rods, tubes, strips, etc. Commonly used extruded metal materials include aluminum, copper, magnesium, titanium, lead, etc., even brittle materials can also be extruded.

- Advantages : Multiple product specifications, greater production flexibility, small batch production, high dimensional accuracy, good surface quality, lower equipment cost.

- Disadvantages : Large waste loss, low extrusion speed, uneven metal flow.

- Applicable industries : Automotive, ships, construction, electronic industry, consumer goods, etc.

Process : Powder preparation → Mixing and blending → Compacting into mold → Sintering → Shaping → Heat treatment

Powder metallurgy is a manufacturing process that produces precision and highly accurate parts by pressing powdered metals and alloys into a rigid die under extreme pressure. The key process in powder metallurgy is sintering, which heats the parts to bond the powder particles. It is suitable for manufacturing high-precision, complex-shaped parts such as various aerospace parts, automotive parts and medical products. Materials used in metal powder metallurgy include iron, copper, aluminum, magnesium, titanium, chromium, nickel, cobalt, etc. Different materials can be mixed to produce different properties.

- Advantages : Ability to produce complex-shaped parts, high precision, low cost, high material utilization, and reduce post-processing time.

- Disadvantages : lower strength than forgings or castings, not suitable for small batch production.

- Applicable industries : Automotive parts such as tire core, pulley, crankshaft, gears, etc.